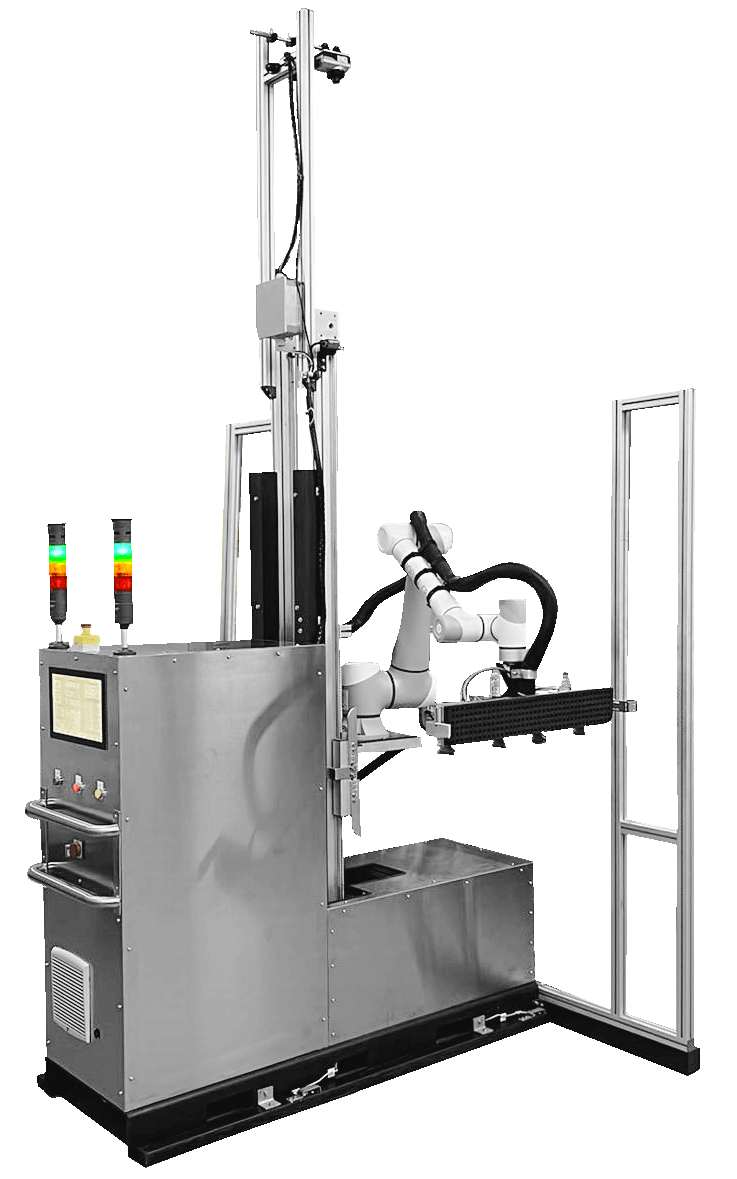

ULX-CR-101

ULX-CR-101 comes with all the necessary components and peripherals and is described as the most "Plug & Play" solution. The system integration could be completed within a working day.

From assembly to de-stacking, from palletizing to screw-driving, from packaging to polishing, from injection molding to welding, co-robot applications provide new levels of productivity to traditional production lines.

Our mission at Ultrand is to provide cutting-edge robotic technology to businesses and individuals around the world. From factory automation to personal robots, our team of engineers and designers can help you create the perfect robotic solution for your needs. We use the latest in artificial intelligence and machine learning to create efficient and adaptive robotic solutions to make life easier and more efficient. We have a variety of robots to offer - from humanoid robots to industrial robots, we can meet your robotic needs. Contact us today to learn more about how our robotic solutions can help you!

Easy to use GUI

Without complexity, using predefined recipes, user can select the product type that will be loaded for depalletizing in the system.

1st Step Product type selection

2nd Step Total layer number selection

3rd Step Depalletizing start

Smart safety system

Using a specific smart camera trained with Artificial Intelligence, the system provide extra safety while sending a stop signal to the robot, when someone enters in the depalletizing working area.

Using cutting edge technology by ADLINK Neo Camera Artificial Intelligence (AI) system, the installation of typical safety systems such as safety light curtains could be avoided. Using new technologies the system provides the best possible portability and user friendly operation .

System Characteristics

Specifications

- IP 54.

- Up to 40 products/min.

- Max pallet height 2400mm.

- UPS for safe shutdown.

- Max speed 80mm/s.

- Pallet existence sensors.

- Conveyor "safe to place" sensor.

- Capability of machine vision addition to achieve specific orientation.

- Capability of remote assistance for technical

support. - Operating temperature 0°C - 50°C.

Details

- Massive product gripping using foam gripper.

- System total weight: 400kg.

- Fast product picking.

- Maximum pallet dimensions: 1000Χ1200mm

Power

- AC Voltage: 230 Volts.

- Amplitude : 32 Amperes Max.

- Number of phases : 1-phase, 50/60 Hz.

Minimal spatial footprint

ULX-CR-101 requires just an area of 760Χ1600mm. Including the space that the 2 pallets cover, there is a maximum space demand that is less than 3 square meters.

Contact Us Today

Fill out the form below and we'll get back to you as soon as possible. We're here to answer any questions about ULX-CR-101 or any other robotics, machine vision, and industrial automation need.