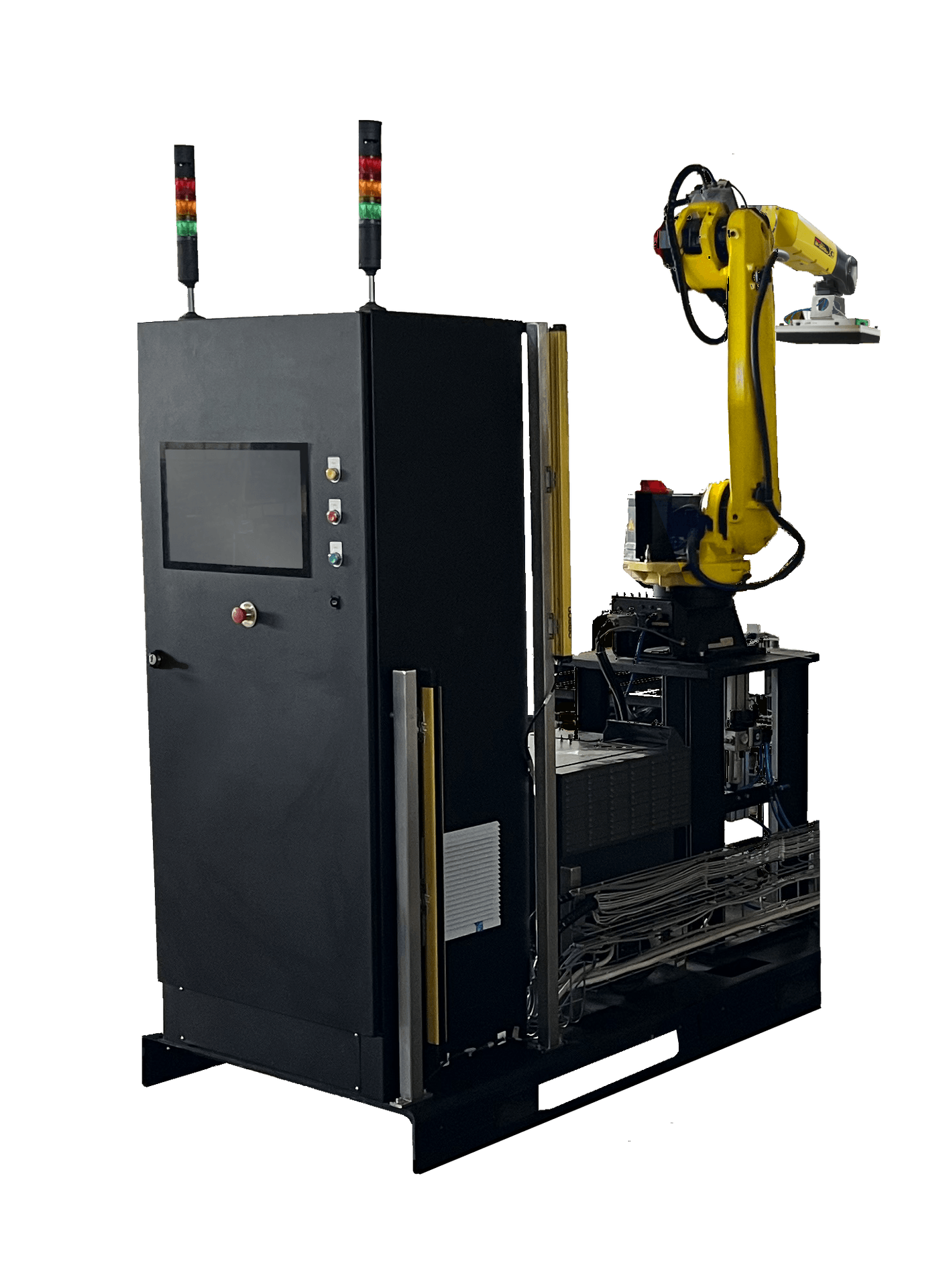

ULX-FC-M20I-202

ULX-FC-M201 is a compact palletizing machine used to automate the process of stacking and arranging products or materials onto pallets.

Process

Receive products

The ULX-FC-M201 machine receives products or materials from an upstream production line or conveyor belt. These items are usually in a continuous flow.

Sorting and Orientation

The ULX-FC-M201 machine incorporate sensors to identify and sort the incoming items. It ensures that the products are correctly oriented and aligned for efficient palletizing.

Layer Formation

The ULX-FC-M201 machine typically creates product layers by arranging a predetermined number of items in a specific pattern. This pattern can be customized based on factors like product dimensions, weight, and stacking requirements. As each layer is formed, the ULX-FC-M201 starts stacking subsequent layers on top.The stacking process continues until the desired number of layers or a specific height is reached.

Interlayer Placement

In some cases, the machine may also insert interlayer sheets, slip sheets, or paper disk between layers to provide additional stability, protection, or separation.

Easy to use GUI

Without complexity, using predefined recipes, user can select the product type that will be loaded for palletizing in the system.

1st Step Product type selection

2nd Step Total layer number selection

3rd Step System status

SAFETY CURTAINS SENARIOS

SENARIO 1) Until the operator chooses side for palletizing, the safety curtains A2 and B2 are activated, If the operator passes through the curtains the system stops.

SENARIO 2) As the operator selects side A for palletizing, safety curtains B2 and A1 are activated, If the operator passes through these curtains the system stops so the robot can't harm the operator.

SENARIO 3) As the operator selects side B for palletizing, safety curtains A2 and B1 are activated, If the operator passes through these curtains the system stops so the robot can't harm the operator.

Details

- Massive product handle, using foam

- Quick product selection

- Maximum pallet dimensions: 1000X1200mm

- Up to 8 products/min

- Max pallet height 1800mm

- UPS for safe shutdown

- Pallet existence sensors

Contact Us Today

Have any questions or inquiries about ULX-FC-M201 ? Fill out the form below and we'll get back to you as soon as possible. We're here to help!